When are two catalysts really different?

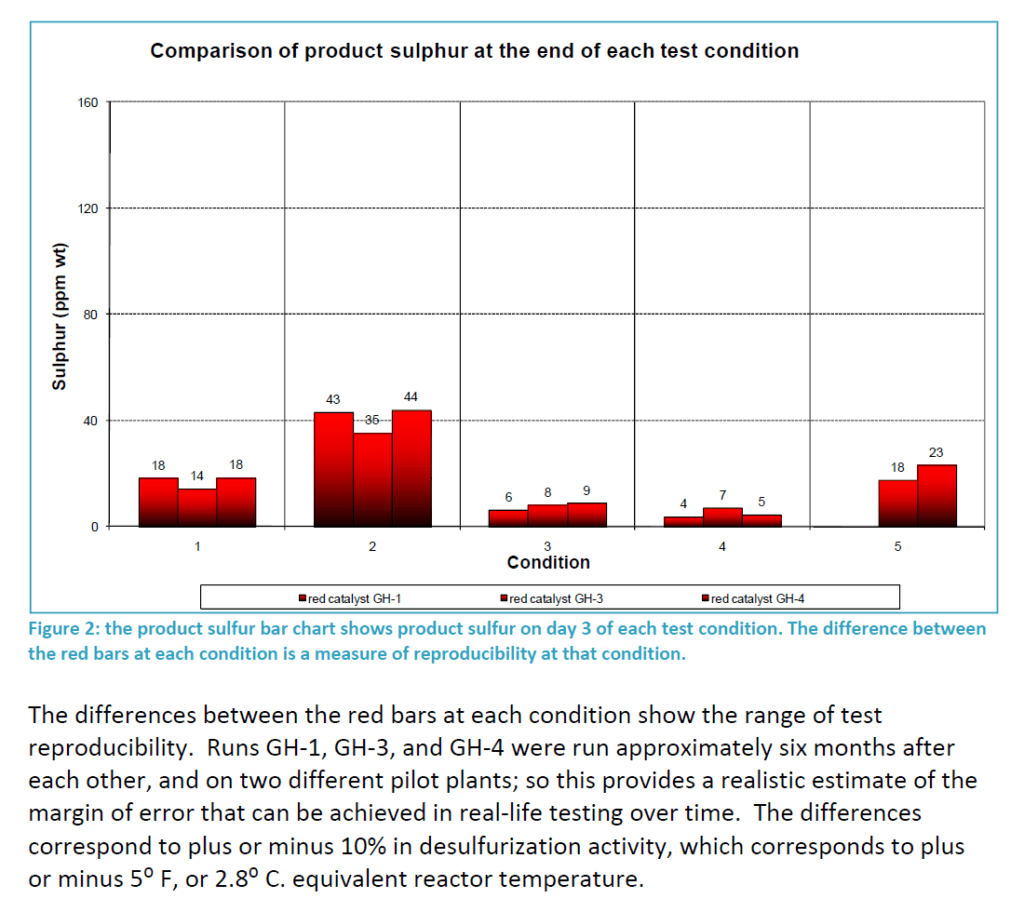

When testing catalysts, we always dedicate one of the four reactors to a reference catalyst sample, to determine the margin of error. For example, here is an excerpt from Hoekstra Research Report 2 showing results for the Albemarle KF767 reference catalyst in three different pilot plant runs testing diesel fuel desulfurization catalysts:

Most often, the differences between different catalysts fall within our known margin of error. We do not call those catalysts different (but catalyst marketers often do). We only separate catalysts into Tiers where there are significant gaps between clusters that exceed the margin of error.

Variance in commercial production

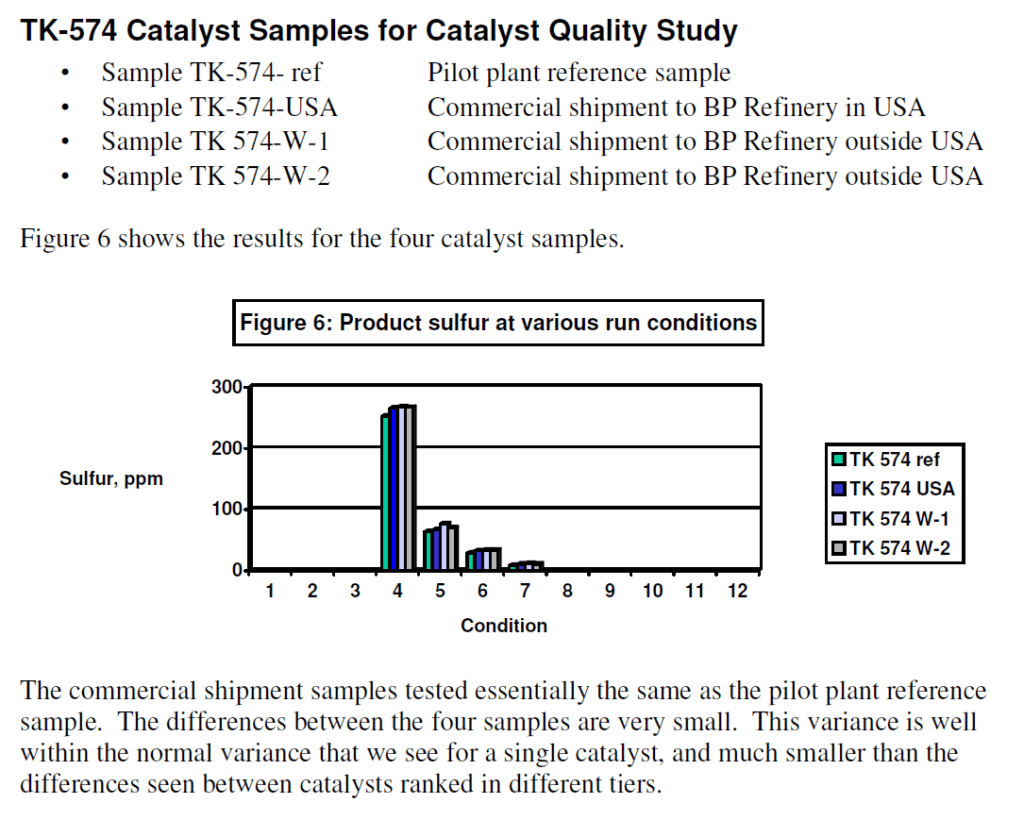

In 2006, BP tested four samples of Haldor Topsoe’s TK-574 catalyst received in different shipments made at different times from different production batches to different BP facilities. This standardized pilot plant test had 12 test conditions:

The data shown here for four different production samples at four different test conditions assured BP refineries they could expect the TK-574 catalyst they received to perform as well as the pilot plant reference sample.

Hoekstra Research Report 2 shows that not all pilot plant testing, and not all commercial production, is as consistent as that shown here, in fact, this level of consistency is rare. And we proved that most claims of a “better” catalyst are not justified when the evidence given is scaled against the real-life sources of variance in the data.

Separating signal from noise

Often, refiners judge difference in catalyst performance by comparing data from different test facilities, or (worse!) from different catalyst suppliers’ test facilities, or (even worse!) from differences in commercial data. Such judgements are inevitably clouded by differences in pilot plants, feeds, operating conditions and the noise of commercial operation. This increases the margin of error to the point where it is impossible to differentiate the effect of the catalyst from the noise.

This is not to say commercial performance data is not useful! In fact, it is useful for the most important purposes, including determining the profitability of the operation! But, for the purpose of choosing catalysts, reliable standardized independent pilot plant testing, using multiple standard feeds and reference catalysts, is the right way to go. In fact, is the only way to reliably judge the independent effect of a different catalyst on commercial performance.

Conclusion

Today, when good independent catalyst test data is readily available to anyone at negligible cost, all refiners should be using it to help their catalyst selection.

Recommendation

Which competitive catalysts are you considering for upcoming reloads? We have the hard data and knowledge base to help you do a good apples-to-apples comparison of their profit impact in your unit.

If you’re not yet in our user group, your first step is to buy Hoekstra Research Report 3. It is easy to do . . no contracts, no lawyers, no non-disclosure agreements are needed. Just use the sample invoice in this brochure as a template to prepare a purchase order to buy Report 3. Then convince your boss to sign it, and E-mail the PO to us today.

For $50,000, you’ll get Report 3 at the speed of light and immediate access to $1,600,000 of scientific information plus technical service that will help you make your refinery’s best-ever catalyst reload decisions in 2022. Don’t live for years with inferior results just because you decided to try to do the job without this inexpensive, quality tool.

George Hoekstra

+1 630 330-8159